FDA - Imported Food Field Inspection App

This project modernized the FDA’s food inspection process with a user-friendly mobile solution, replacing outdated tools and optimizing workflows to improve efficiency and accuracy.

Client: FDA – US Food & Drug Administration

Industry: Government

Platforms: Tablet App, iOS Native

Role: Lead Product Designer & Manager

Design Team: Myself, UX Designer, UX Researcher

Client Team: Stakeholder, SME, Engineering Lead & Engineering Team

Time Frame: 6 Months

**View the final designs and project outcomes by scrolling to the bottom of the screen.

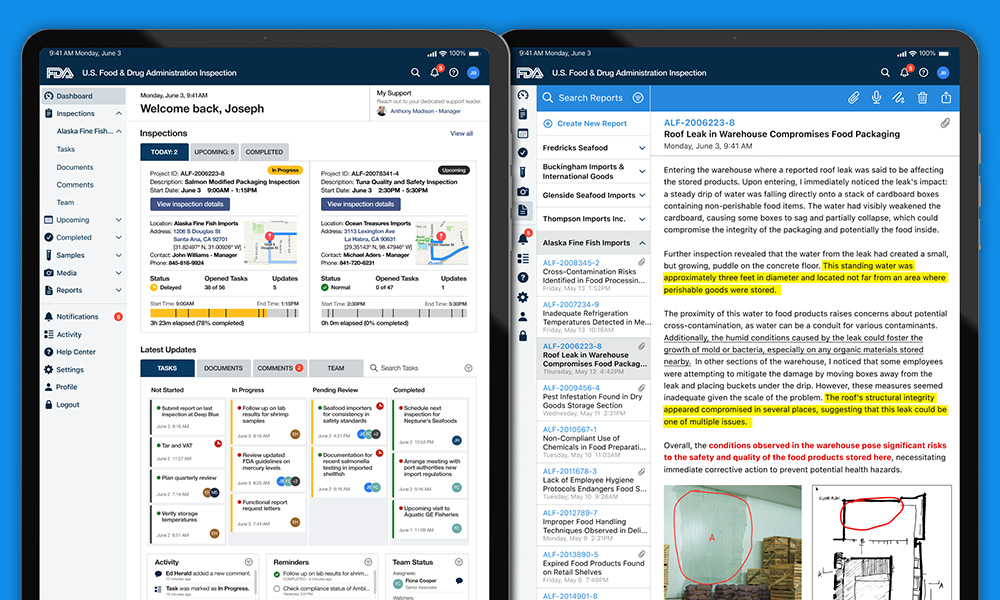

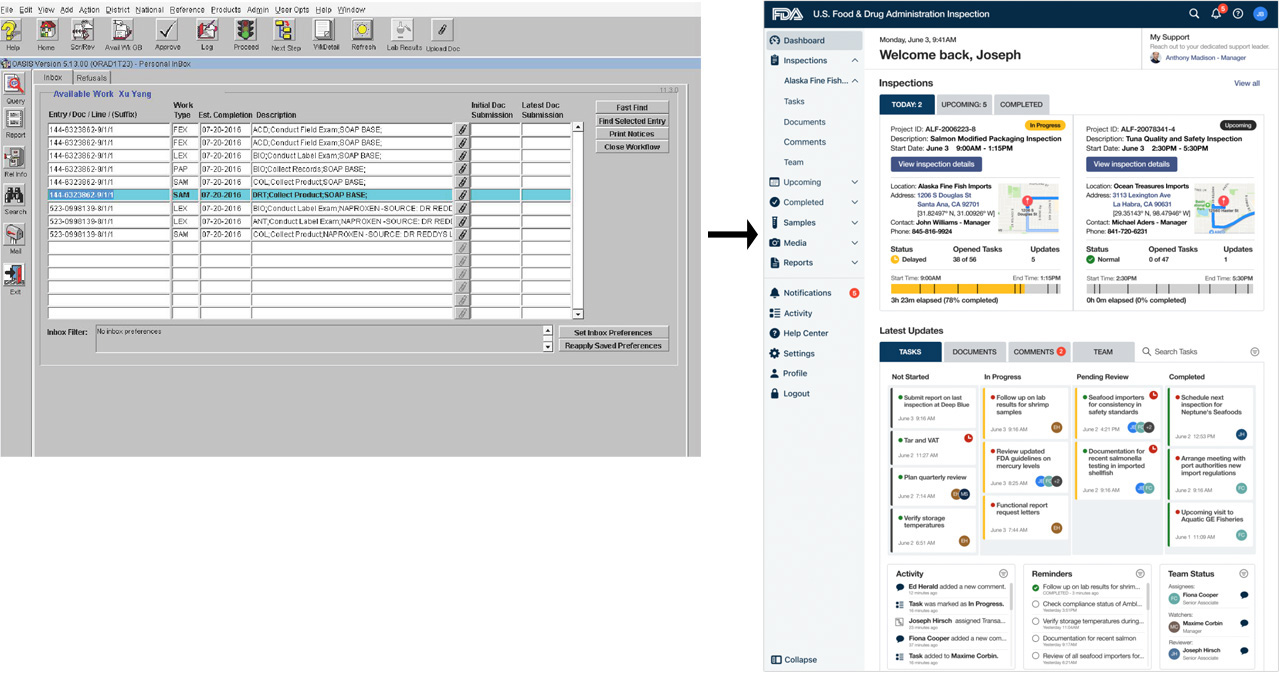

Before & After

Context

FDA imported food inspectors protect public health by ensuring imported food meets U.S. safety standards and complies with regulations to prevent risks to consumers.

- Maintain Compliance Oversight: Inspectors ensure that food importers follow regulations by overseeing operations, reviewing safety procedures, and identify violations.

- Document Observations and Violations: Inspectors are responsible for collecting critical data by documenting observations, and recording violations to uphold safety standards during their inspections.

- Conduct On-Site Inspections: They conduct physical inspections on-site at multiple locations, reviewing operations and facilities to verify alignment with regulations.

Problem

Field Inspectors Impact:

- Inspection Workflows: Inefficient workflows slow inspectors down, causing delays and inaccuracies, and require improvements to enable faster, more precise reporting.

- Documentation Process: A cumbersome documentation process creates challenges for inspectors, reducing accuracy and usability, and highlights the need for simplification.

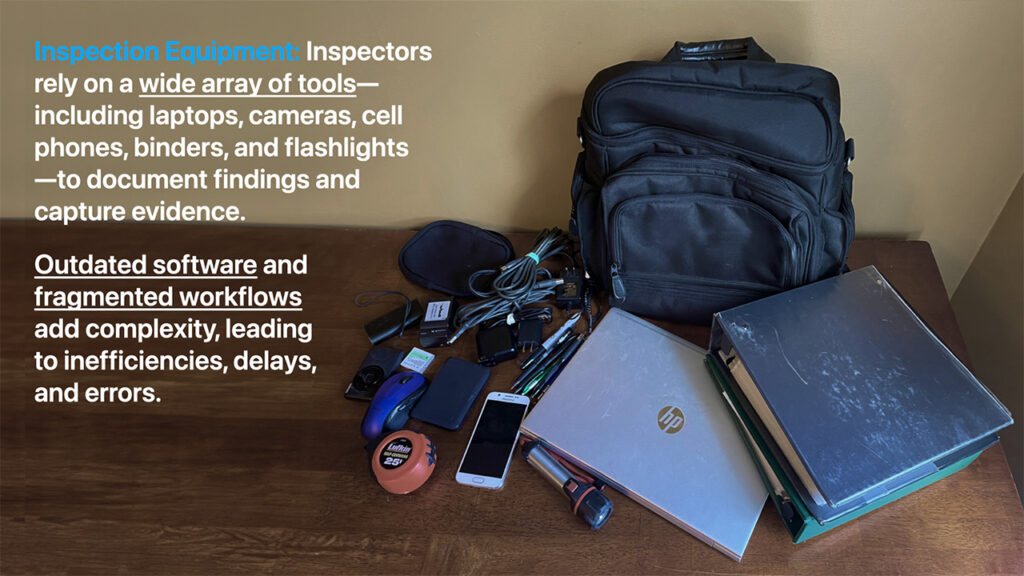

- Inspection Equipment: Inspectors rely on a wide array of tools—including laptops, cameras, cell phones, binders, and flashlights—to document findings and capture evidence. Outdated software and fragmented workflows add complexity, leading to inefficiencies, delays, and errors.

- Tight Schedules & Back-to-Back Inspections: Inspectors face daily challenges managing tight schedules and consecutive inspections. The lack of effective scheduling and navigation tools makes it difficult to plan and complete inspections efficiently.

Business Impact:

- Environmental Challenges: Varying inspection site sizes and limited wireless connectivity disrupt operations and require adaptable solutions to maintain seamless functionality.

- Operational Inefficiencies: Fragmented tools and outdated processes cause delays and errors, reducing the organization’s overall productivity.

- Cost Implications: Inefficient workflows and excessive reliance on paper-based systems increase operational costs.

- Compliance Risks: Delays and errors in reporting undermine adherence to regulatory standards, posing risks to public safety.

Objective

-

Streamline Inspection Workflows: Optimize processes to minimize delays and ensure faster, more efficient task completion.

-

Simplify the Documentation Process: Improve usability to make documenting and recording inspection details more accurate and user-friendly.

-

Design a Mobile Solution: Replace outdated tools and fragmented workflows with a single portable device to improve inspector efficiency.

-

Maintain Seamless Operations: Ensure uninterrupted connectivity by addressing site size and wireless connectivity challenges.

-

Optimize Rigorous Schedules: Provide scheduling and navigation tools to help inspectors effectively manage single or consecutive inspections in a day.

UX Process:

Empathize

Tasks:

Reviewed Stakeholder requirements

Educated on inspection training and FDA operating procedures

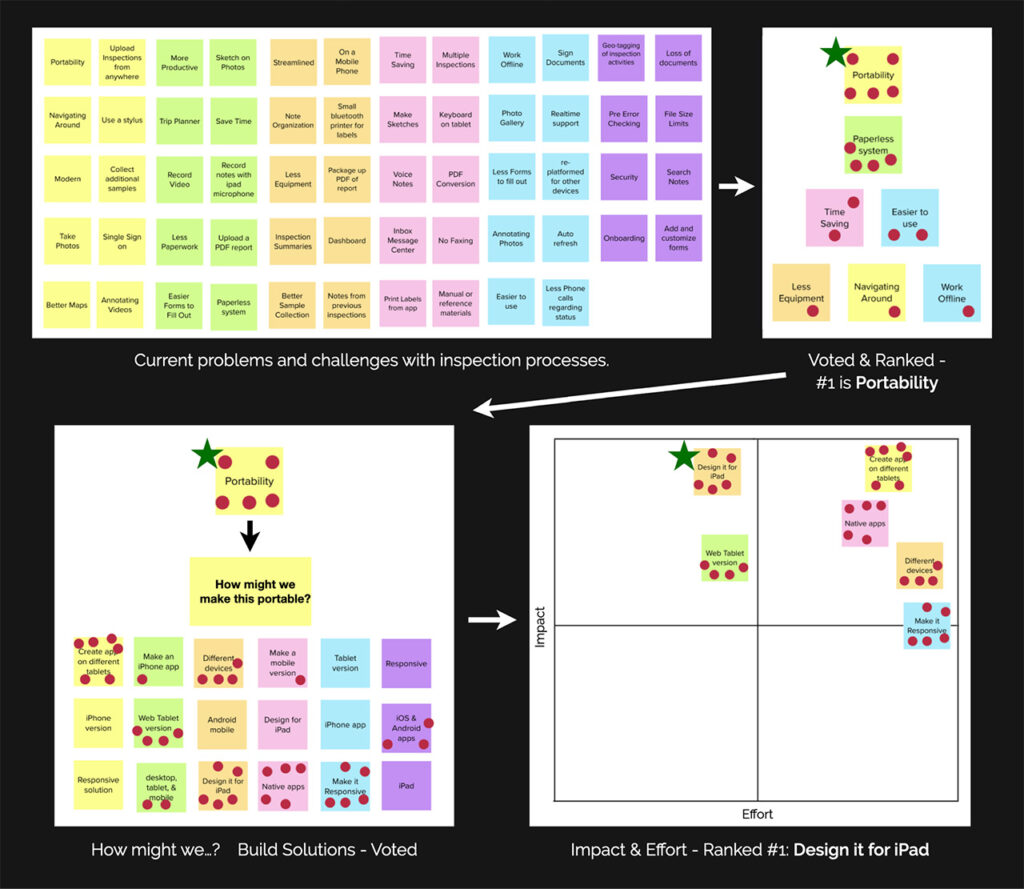

Created a Problems & Challenges Matrix

Conducted interviews with Inspectors and Stakeholders

Shadowed field inspections with inspectors

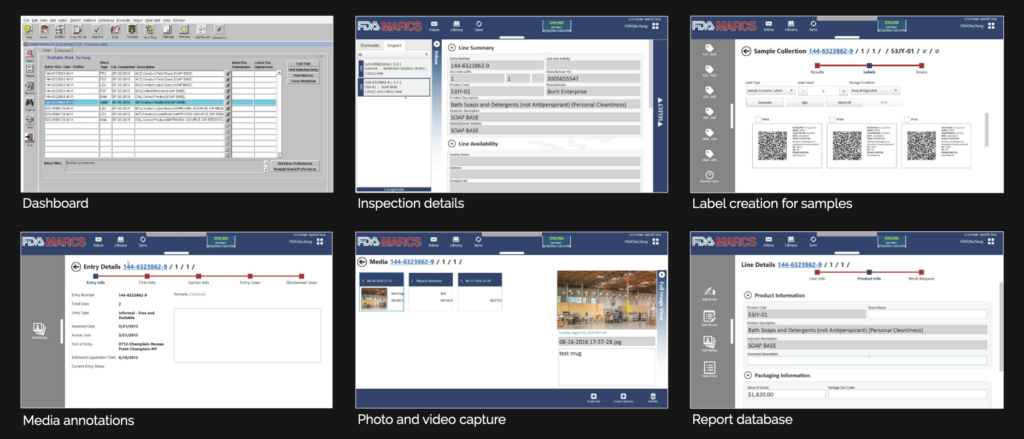

Performed product evaluation of current inspection software

Stakeholder Requirements

Key Findings:

- Enhanced Workflow Efficiency: Stakeholders emphasized the need to optimize inspection processes to minimize delays, reduce errors, and improve overall productivity.

- Improved Data Accuracy and Reporting: Reliable and precise documentation is critical to ensuring compliance and maintaining regulatory standards.

- Adaptability to Operational Challenges: Solutions must address varying inspection site conditions, including limited connectivity and diverse operational environments, to ensure seamless functionality.

- User-Centered Technology Solutions: Stakeholders highlighted the importance of modern, integrated tools to replace fragmented and outdated equipment, enhancing usability and inspector satisfaction.

Problems & Challenges Matrix

Interviews & Shadowed Claims Adjusters

Claims Adjusters:

- Difficulties in filling out forms, retrieving information, and operating offline because of inconsistent connectivity.

- They are required to carry a large amount of equipment for every inspection.

- Extended working hours due to frequent phone calls with the back office and inspection report submission delays.

Stakeholders:

- Improve Inspector productivity by maintaining their focus and efficiency during inspections.

- Encourage Managers to take more responsibility during and after inspections.

- Simplify the process of accessing information, internal communicating and better technology for Inspectors.

If we had a better system for logging inspections on-site, it would save so much time and allow me to focus on food safety instead of being bogged down by paperwork.

Taylor Verona - Senior Inspector

Product Evaluation

Shadowed Inspectors during field inspections

Conceptualize

Tasks:

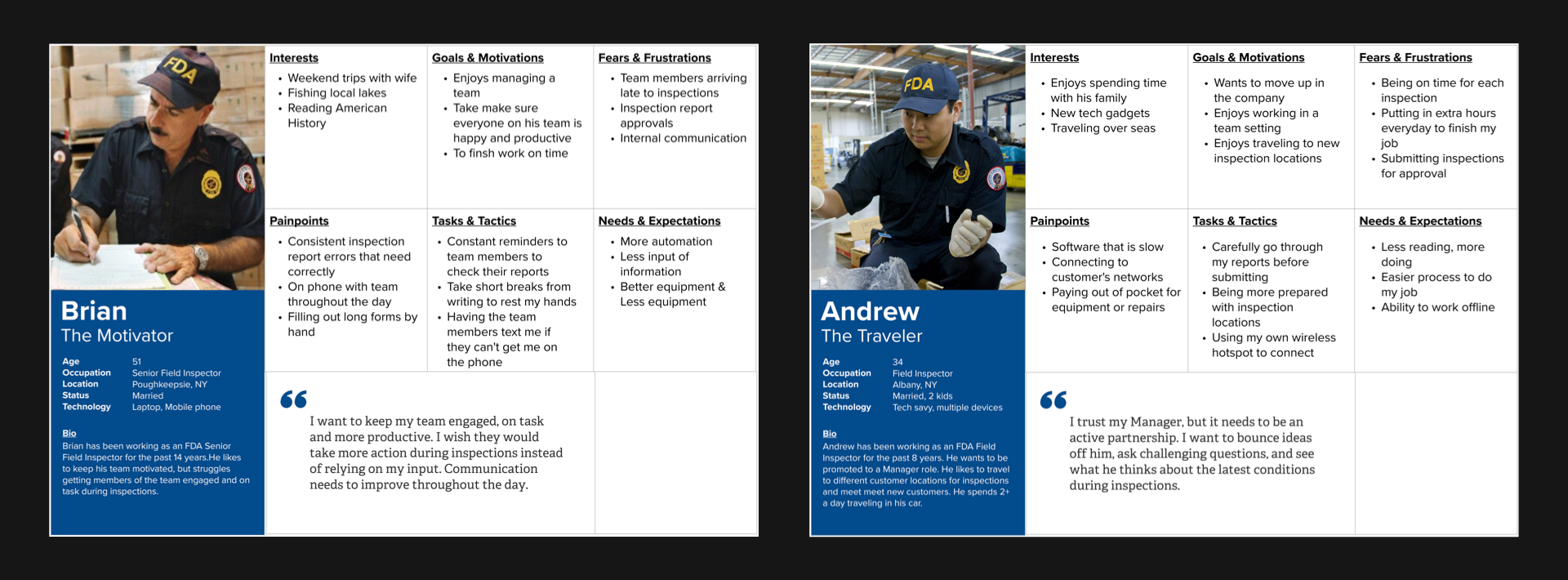

Developed User Personas

Created Journey Map

Conducted Foundational & Exploratory Research

User Personas

Key Findings:

- Technology Limitations: Inspectors are hindered by outdated software, slow system performance, and connectivity challenges.

- Inefficient Workflows: Excessive manual paperwork and cumbersome processes increase workloads and delay tasks.

- Communication Barriers: Ineffective communication tools create challenges in collaboration and information sharing.

- Financial Strain: Inspectors often cover personal costs for essential work equipment.

- Drive for Improvement: Despite frustrations, inspectors are committed to their roles and strongly advocate for modernized systems to improve team performance and streamline processes.

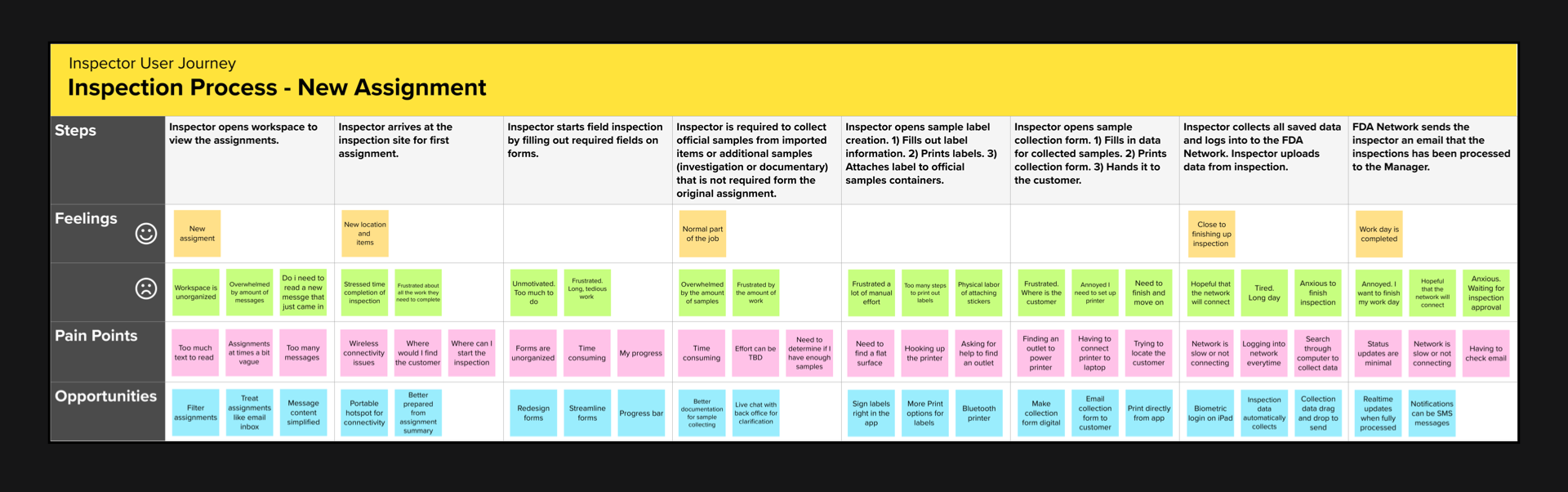

Journey Map

Key Findings:

- Inefficient Processes: Inspectors face delays and challenges due to outdated tools, fragmented workflows, and cumbersome procedures.

- Need for Simplified Documentation: Streamlining and simplifying documentation processes would improve accuracy and reduce frustration.

- Technology Gaps: Better systems and updated technology are critical to improving efficiency, accuracy, and communication in inspections.

- Improved Communication: Clearer communication between inspectors, teams, and FDA headquarters would enhance coordination and ensure smoother operations.

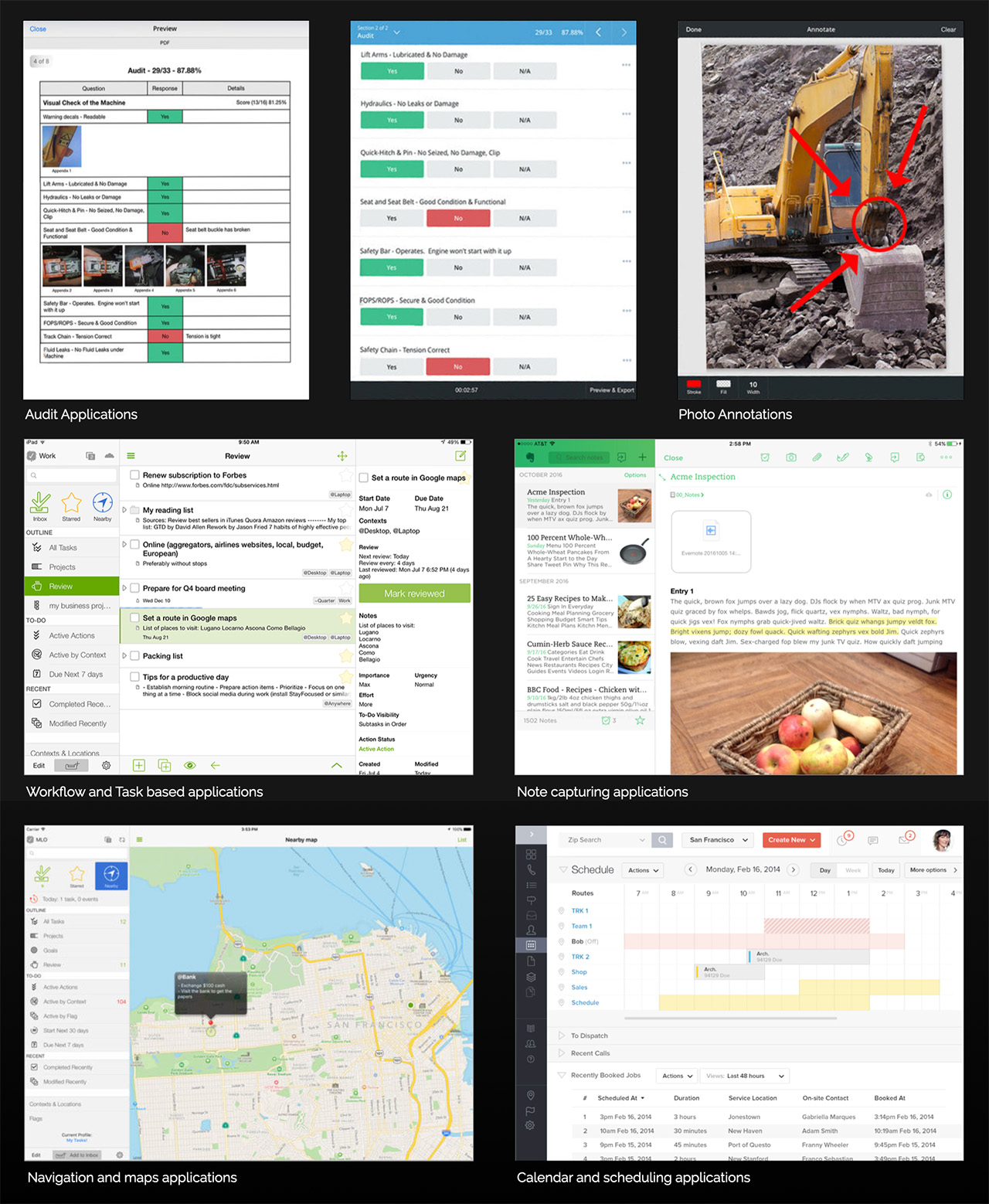

Foundational & Exploratory Research

Design

Tasks:

Developed Prototype

Conducted User Testing

Built High-Fidelity Designs

Created Design System

Prototype & User Testing

Key Findings:

These were new and updated features introduced into the prototype and tested with inspectors during user testing to evaluate the usability and effectiveness of the prototype.

-

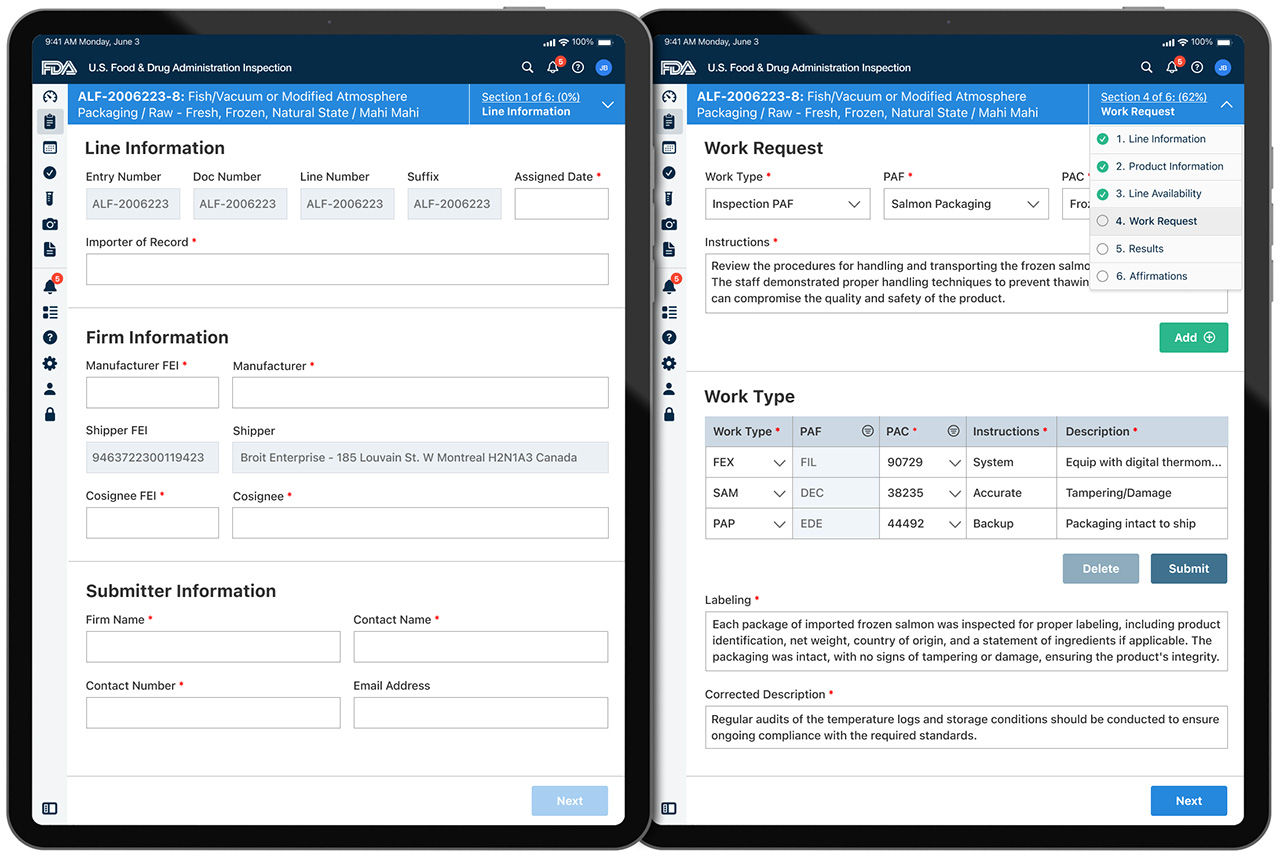

Introduced Touchscreen: Provided smooth and easy task interactions on a tablet, transitioning from the previous laptop-based system

-

Intuitive Interface: Provided a more user-friendly and seamless experience

-

Effortless Global Navigation: Simplified movement throughout the app

-

Optimized Forms: Streamlined for quick and easy completion

-

Searchable Content: Allowed easy access to critical information

-

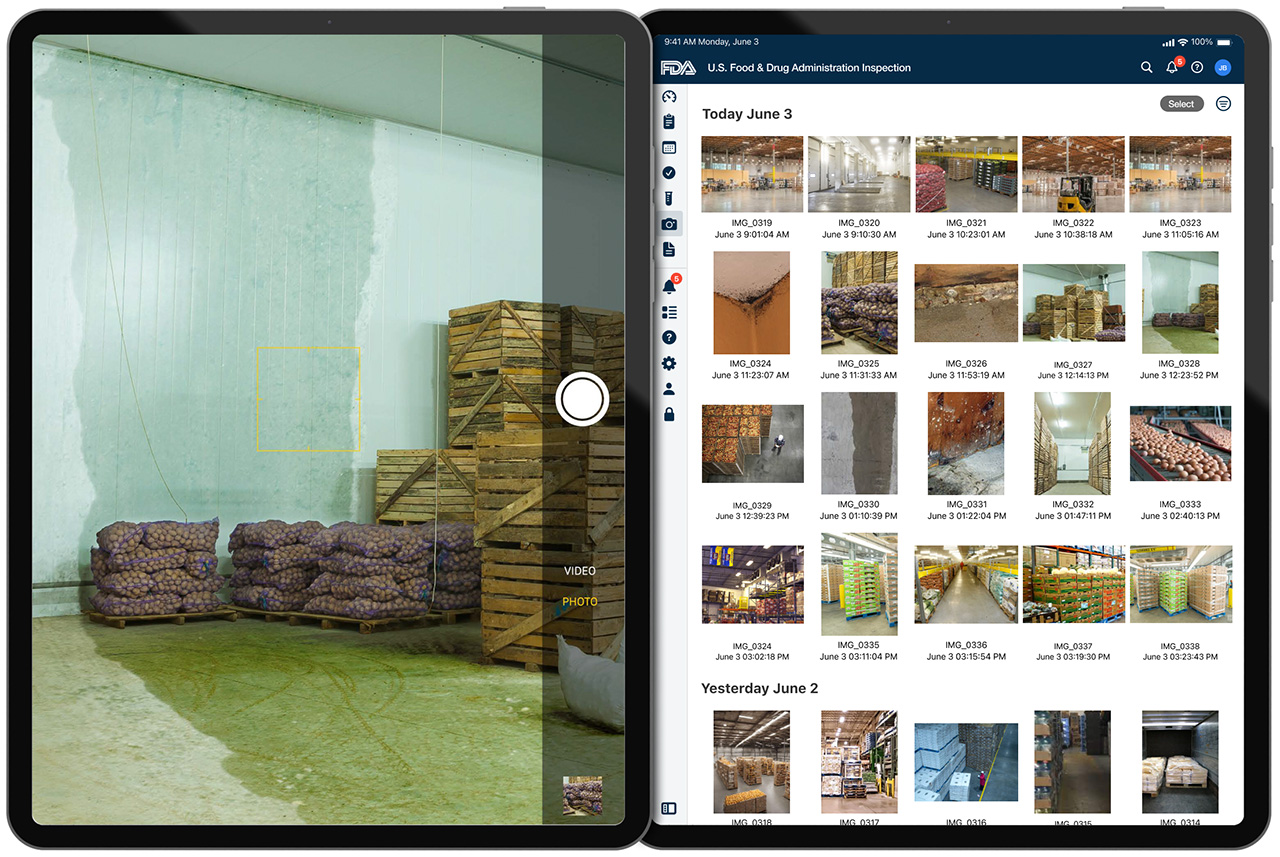

New Integrated Camera: Captured photos and videos directly within the app

-

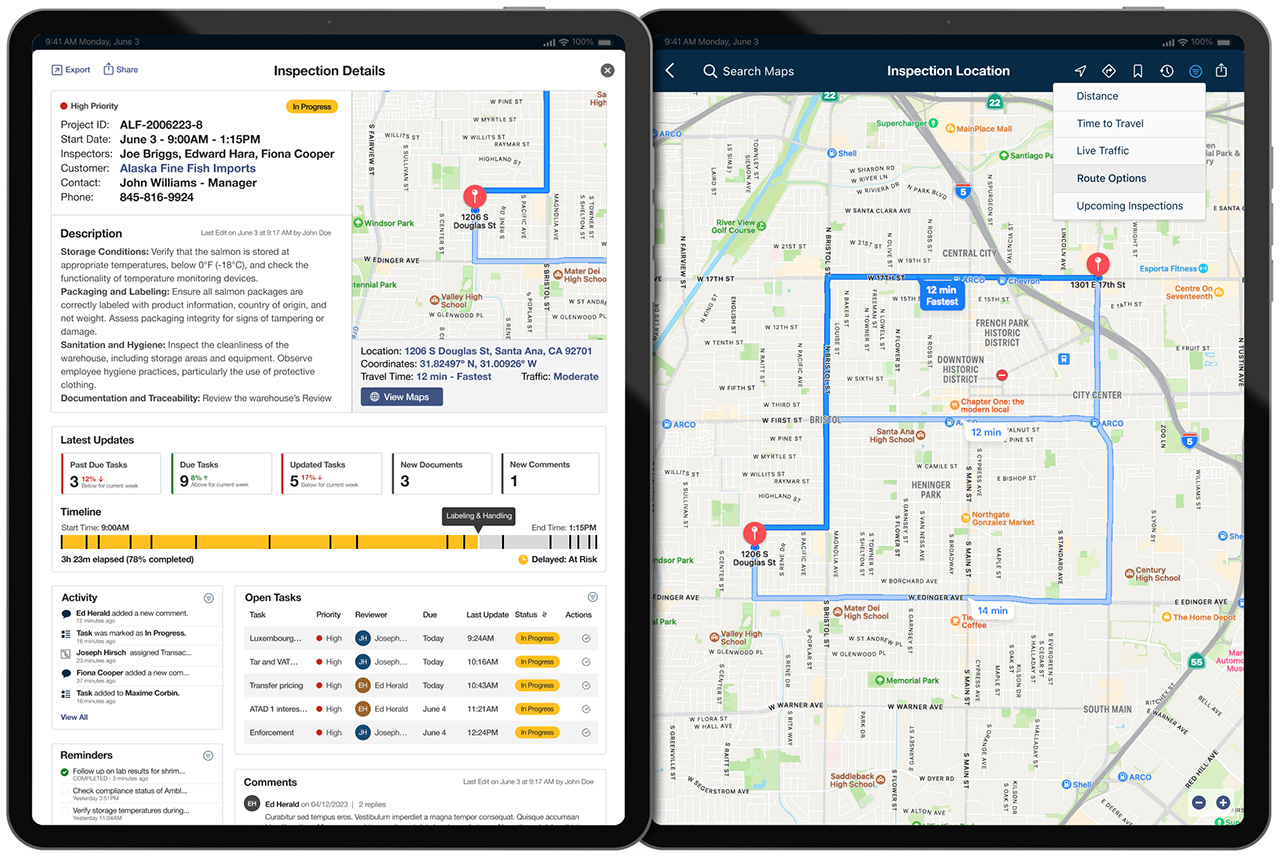

Enhanced GPS: Improved navigation and trip planning capabilities

-

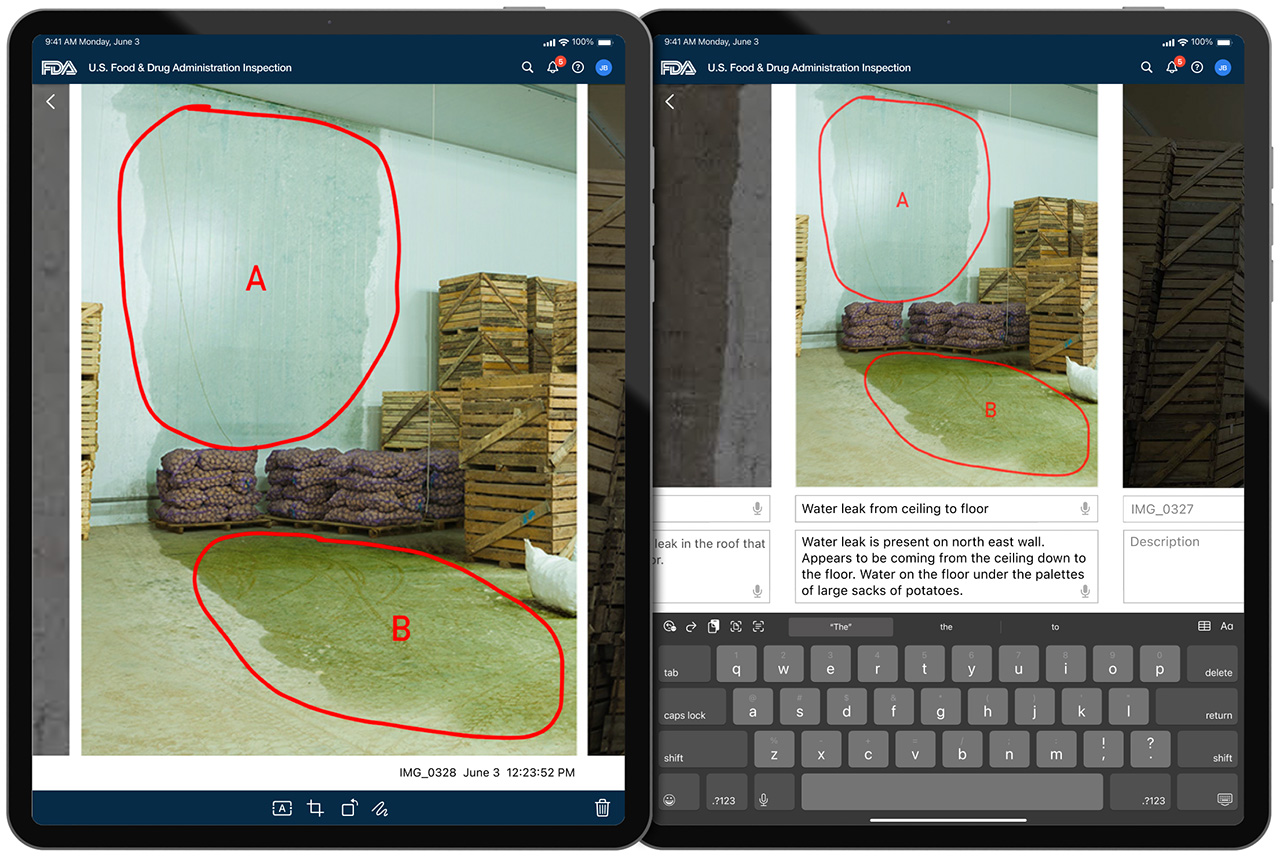

Flexible Handwriting: Supported seamless note-taking with a stylus

-

Hands-Free Voice-to-Text: Enabled efficient and convenient note-taking

Project Outcomes

Key performance indicators (KPIs) are based on 6 months of user data collected from FDA inspectors and company analytics.

Inspector Impact:

-

27% Reduction in Inspection Times: Faster data collection saved inspectors valuable time in the field, enabling them to complete tasks more efficiently.

-

22% Increase in Inspections Per Week: Streamlined workflows tools allowed inspectors to conduct more inspections weekly.

-

52% Reduction in Missed Violations: Ensured greater compliance rates and safer food practices.

-

39% Decrease in Documentation Errors: Improved reporting reliability minimized corrections and ensured accuracy.

-

82% of Inspectors Reported a Better User Experience: The app’s intuitive design reduced cognitive load and stress.

Business Impact:

-

18% Annual Cost Savings: Achieved through reduced paper use, better route planning, and fewer follow-up inspections, directly improving operational cost efficiency.

-

27% Reduction in Inspection Times: Improved efficiency lowered labor costs and enhanced organizational productivity.

-

39% Decrease in Reporting Errors: Guided data entry and validation checks enhanced accuracy, reducing time spent on corrections and improving operational consistency.

-

84% Positive Feedback from Inspectors: Improved job satisfaction and ease of completing inspections contributed to higher retention rates, reducing recruitment and training costs.

Knowledge Gained

-

Simplified Data Entry: Intuitive forms and voice-to-text enabled seamless input, highlighting the value of user-friendly methods to reduce friction and improve accuracy in future projects.

-

Instant Access to Information: Searchable databases provided quick reference to regulations, reinforcing the need for instant access to support decision-making.

-

Customization and Workflow Flexibility: Inspectors adapted the app to their needs, demonstrating the importance of designing adaptable solutions for unique workflows.

-

Real-Time Communication: Messaging tools enabled immediate updates, emphasizing the need for seamless collaboration in future systems.

-

Navigation and Planning: GPS and mapping features streamlined site planning, showing how optimized navigation improves time and resource management.

-

Camera Integration: Easy photo and video capture simplified documentation, proving the value of integrated tools to enhance accuracy and reduce reporting effort.

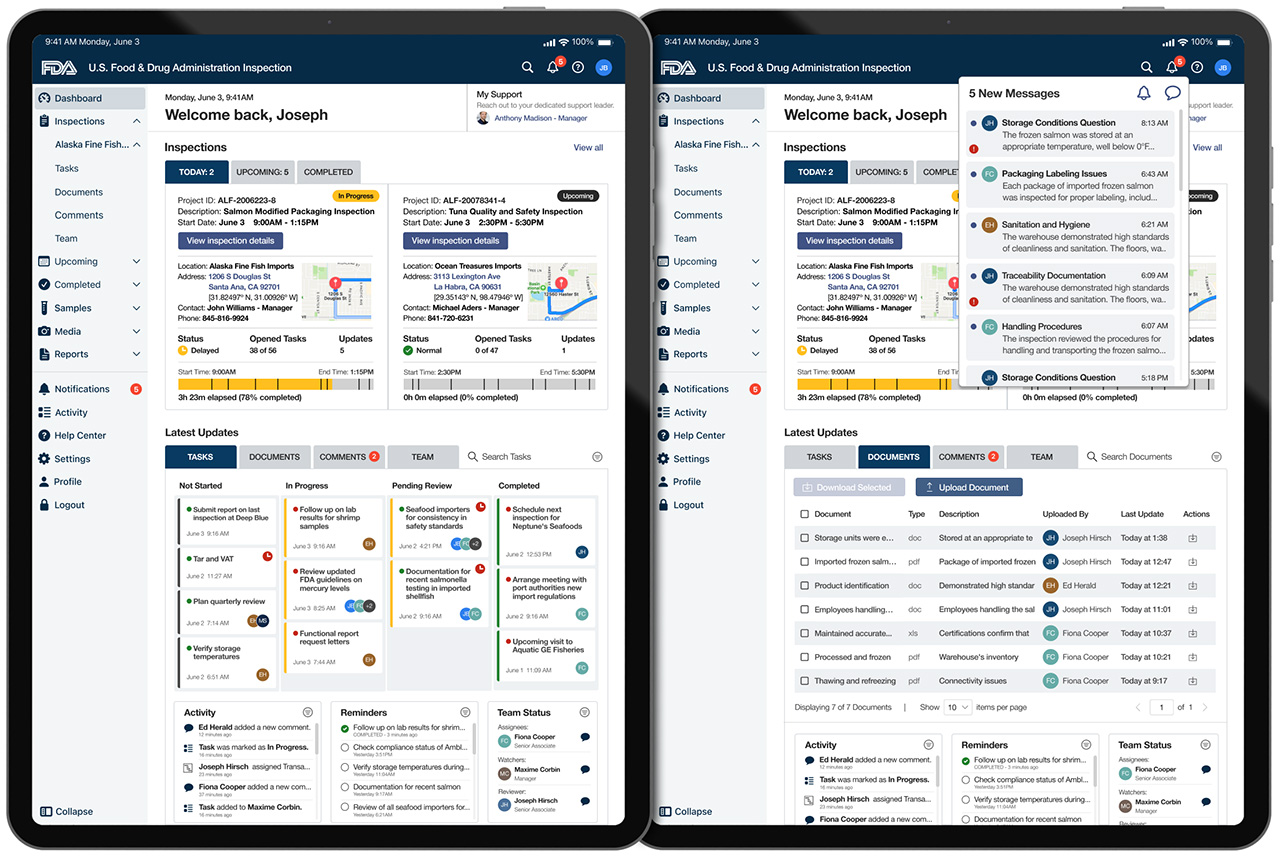

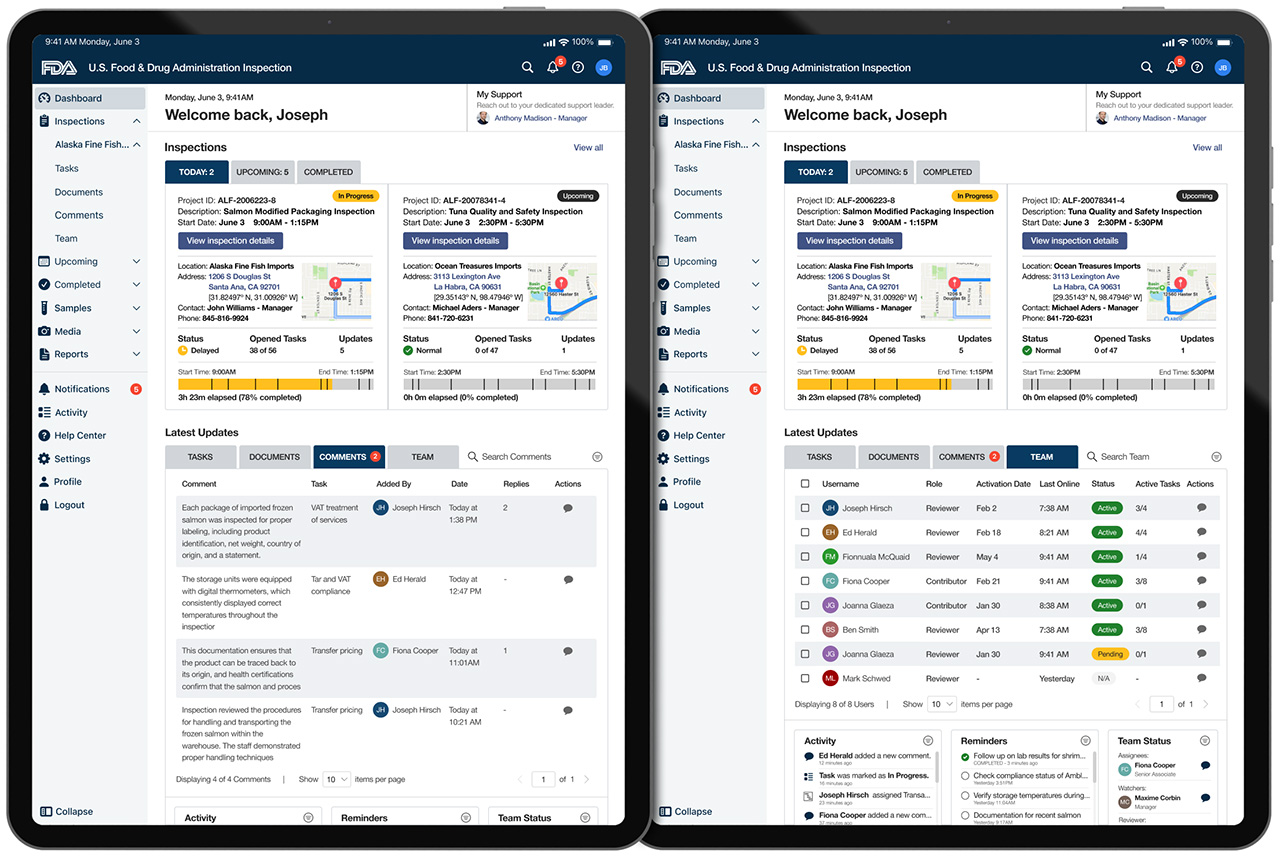

Final Designs

Inspection Dashboard

Inspection Dashboard (continued)

Inspection Details & GPS

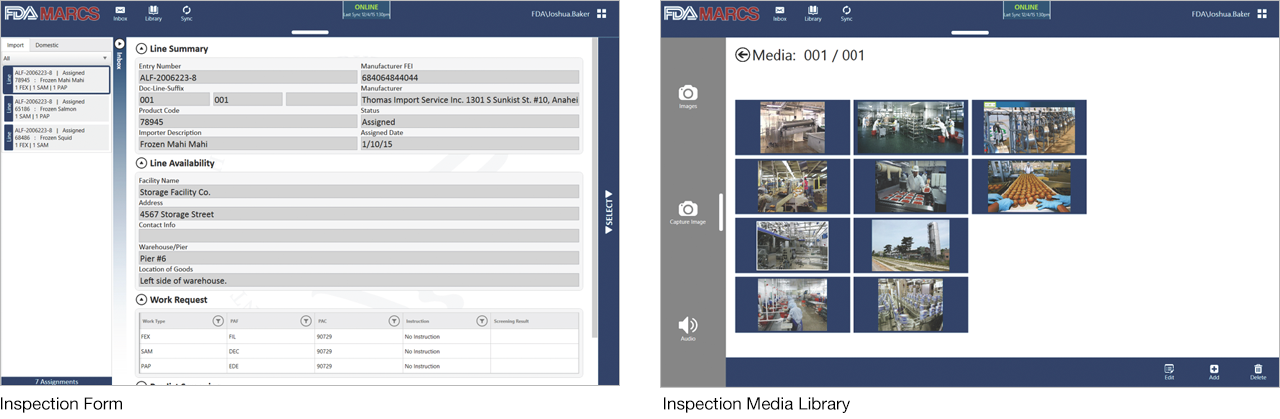

Inspection Forms

Inspection Sample Collection & Labels

Inspection Visual Documentation Library

InspectionVisual Documentation - Markup

Inspection Reports